Microwave drying

Drying is an energy-intensive operation which can have a large effect on product quality. Microwaves can generate a uniform heat field inside the material and increase the constraint on vapor to leave the material.

Because of water change of state, or when additional processes are involved (curing for instance), controlling the electromagnetic field for proper results requires real time computations. The development and validation of models for heat generation and concurrently solvent flow require methods besides electromagnetic propagation in a fixed composition medium.

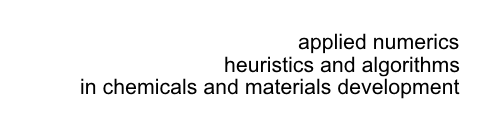

wood structure for drying simulation

Microwave assisted synthesis

Microwave assisted synthesis has been experimentally tested in various cases, allowing to obtain original products or enhanced yields. As for example, the preparation of bi-metallic nano particle of Pd and W supported on mesoporous carbon, as an efficient catalyst for hydrogen fuel cells, and various controlled radical polymerizations or step-growth polymerizations.

Although the efficiency of microwave synthesis is credited to the specific temperature profile and the temperature control, time has evolved since tests with kitchen ovens and a more efficient use of the electromagnetic field / materials response is presently possible.

commercial equipment for MW assisted peptide synthesis

Patterned deposition by ink jet printing

Ink jet printing is often used instead of transfer printing for production of active components, as for instance Thin Film Transistors from amorphous oxide semiconductors.

Handling the constraints of circuit design (2d or 3d) and effective ink design (jettability, pinning, reliability, ...) involve a mix of several classical methods in fluid flow.

ink jet printed circuits at GeorgiaTech

Nanopowders from sol-gel

Among various methods to obtain oxide nanopowders, aqueous and non-aqueous sol-gel methods allow to finely control complex compositions and dopants.

Examples of obtained products are BZN (Bi1.5ZnNb1.5O7, high dielectric constant material that combines low dielectric losses with an electric-field dependent permittivity), MnFe2O4/CoFe2O4, NaGd(WO4)2:Yb(3+)/Tm(3+) (a single-component and warm-white-emitting phosphor), Ce2Ti2O7 family.

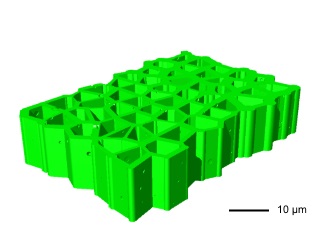

Cr doped TiO2 nanospheres

Thin films from electrodeposition

Besides vacuum technology deposition, solution methods are investigated for large area, lower cost applications. Morphology and composition control rest on solution components, supports and current waveforms.

Examples are WO3 (Tungsten oxide for electrochromic windows), CZTS (Copper zinc tin sulfide for solar cells), NiCoFe (for immobilized catalysis of oxygen evolution reaction).

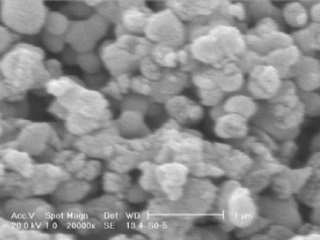

GZO on electrodeposited CZTS